Overview

Resin systems

Surfaces

Colours

Sizes

Overview

Overview

Comtec GRP Gratings are produced by wet moulding and hot curing in a heated mould. The reinforcement consists of continous fibreglass rovings in alternating layers, so the loads are evenly distributed in all directions. Regularly Moulded GRP Gratings have a polyester resin matrix. Glass contect is approximately 35%. Standard colours are green, yellow or grey, other colours are available according to RAL. Various sheets and mesh sizes are also available. Please browse our range of gratings, if you can’t find what you are looking for please contact us.

- Moulded gratings:

- Mesh size/type: 38mm mesh, 50mm mesh, rectangular mesh

- Mini Mesh 19mm, Mico mesh 8mm

Resin systems

Resin systems

Type O™

Type O™ is an architectural grade polyester resin system with an intermediate level of chemical resistance, and is a good choice for commercial or light industrial applications, especially where light moisture is prevalent – it is recomended for less exposed/internal applications. Type O™ is often utilised for public infrastructure applications were it has been proven to outperform traditional timber decking products. This system is manufactured with fire retardant additives.

Type I™

Type I™ is a premium isopthalic resin system. This system provides an intermediate level of chemical resistance and is the correct choice for areas subjected to splash and spill contact with harsh chemicals. This system is an excellent general-purpose resin and is a more favourably priced alternative to the Type V™ vinyl ester system. This system has a flame spread of 25 (Approximately 15) or less. It is our most commonly specificed resin system, and is suitable for external applications.

Type V™

Type V™ is a vinyl ester resin system that provides the highest chemical resistance offered in the industry for a standard resin and has been developed for use in environments where GRP products are subject to frequent and direct contact with the harshest of chemicals including a broad range of acids and caustics. This system has a flame spread of 25 (Approximately 15) or less. This is best suited to the majority of harsh applications where smoke specific characteristics of the Type P™ system are not required.

Type P™

Type P™ is a phenolic resin system that is designed specifically for use where fire resistance, low smoke and low toxic fumes are critical. Type P™ is typically used in offshore applications and confined spaces where such criteria are an absolute necessity. This system is tested in accordance to ASTM E-84 and some products conform to US Coast Guard Approvals Level 2 and 3. This particular resin system has a flame spread rating of 5 and a smoke density rating of 5. This is a highly versatile system for harsh applications.

| Chemical Resistance | Fire Resistance | Low Smoke | Halogen Free | Temperature Resistance | |

|---|---|---|---|---|---|

| Type O™ Polyester | XXX | XXXX | — | — | XXX |

| Type I™ Isopthalic | XXXXX | XXXXX | — | — | XXXX |

| Type V™ Vinylester | XXXXX | XXXXX | — | — | XXXXX |

| Type P™ Phenolic | XXXX | XXXXX | XXXX | XXXXX | XXXXX |

| Chemical Resistance | Fire Resistance | Low Smoke | Halogen Free | Temperature Resistance | |

|---|---|---|---|---|---|

| Type O™ Polyester | XXX | XXXX | — | — | XXX |

| Type I™ Isopthalic | XXXXX | XXXXX | — | — | XXXX |

| Type V™ Vinylester | XXXXX | XXXXX | — | — | XXXXX |

| Type P™ Phenolic | XXXX | XXXXX | XXXX | XXXXX | XXXXX |

| Chemical Resistance | Fire Resistance | Low Smoke | Halogen Free | Temperature Resistance | |

|---|---|---|---|---|---|

| Type O™ Polyester | XXX | XXXX | — | — | XXX |

| Type I™ Isopthalic | XXXXX | XXXXX | — | — | XXXX |

| Type V™ Vinylester | XXXXX | XXXXX | — | — | XXXXX |

| Type P™ Phenolic | XXXX | XXXXX | XXXX | XXXXX | XXXXX |

Characteristic rating per product, X equals score out of 5.

< Scroll the table horizontally for the details >

Surfaces

Surfaces

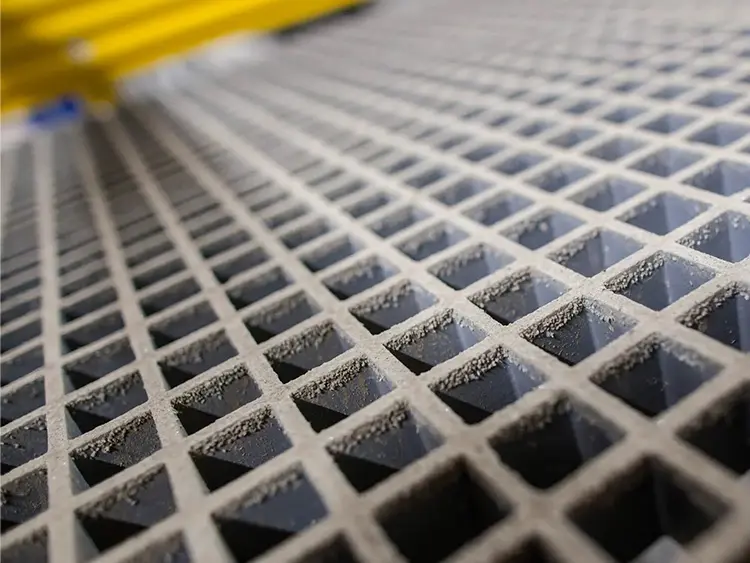

Gritted Anti-slip

This surface is most commonly used in industrial applications. It is very hard wearing and boasts an extremely effective coefficient of friction. Unlike serrated steel, the anti-slip surface does not impact load carrying capacity.

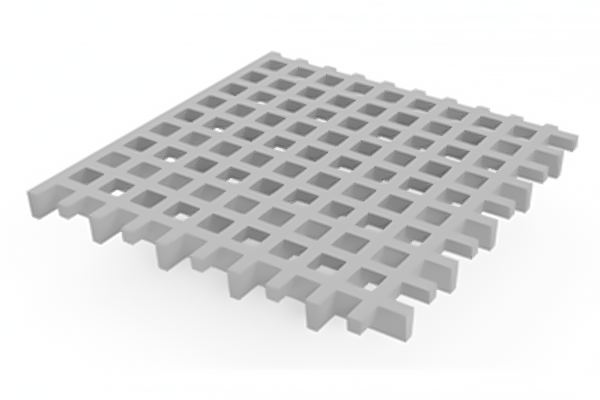

Concave

This is preferred for environments where by-products are commonly caught by serrations, and is hence very often utilised by the food industry. This surface option is also high grip, however does not have a grit applied to it.

Plain

This is widely utilised for guarding and architectural features in a variety of applications. Whilst the aesthetics of the product are clean, the anti-slip properties are not as strong as the other options available.

Colours

Colours

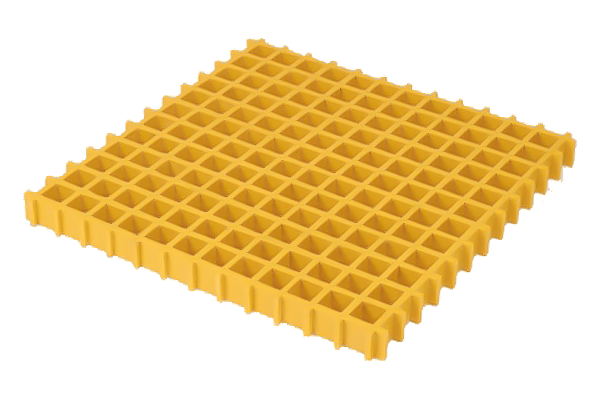

Signal Yellow

Signal Grey

Signal Green

Sizes

Sizes

- At Comtec we stock various thicknesses of material. Stock sheet sizes include:

- 3660mm x 1220mm

- 3000mm x 1000mm

- 2000mm x 1000mm

- These can all be cut to bespoke sizes if required.

38mmx38mm mesh with 32mm*32mm open hole

| Panel Thickness | Weight kg per panel | Panel Size Available | Colour |

|---|---|---|---|

| 38mm | 38 | 2026mm x 1035mm | Grey/Green/Yellow |

| 38mm | 57 | 3017mm x 1035mm | Grey/Green/Yellow |

| 38mm | 85 | 3660mm x 1220mm | Grey/Green/Yellow |

| 25mm | 37 | 3017mm x 1035mm | Grey/Green/Yellow |

| 25mm | 25 | 2026mm x 1035mm | Grey/Green/Yellow |

| 25mm | 55 | 3660mm x 1220mm | Grey/Green/Yellow |

| Panel Thickness | Weight kg per panel | Panel Size Available | Colour |

|---|---|---|---|

| 38mm | 38 | 2026mm x 1035mm | Grey/Green/Yellow |

| 38mm | 57 | 3017mm x 1035mm | Grey/Green/Yellow |

| 38mm | 85 | 3660mm x 1220mm | Grey/Green/Yellow |

| 25mm | 37 | 3017mm x 1035mm | Grey/Green/Yellow |

| 25mm | 25 | 2026mm x 1035mm | Grey/Green/Yellow |

| 25mm | 55 | 3660mm x 1220mm | Grey/Green/Yellow |

50mmx50mm mesh with 42mm*42mm open hole

| Panel Thickness | Weight kg per panel | Panel Size Available | Colour |

|---|---|---|---|

| 50mm | 90 | 3660mm x 1220mm | Grey/Green/Yellow |

| 12mm | 22.5 | 3660mm x 1220mm | Grey/Green/Yellow |

| Panel Thickness | Weight kg per panel | Panel Size Available | Colour |

|---|---|---|---|

| 50mm | 90 | 3660mm x 1220mm | Grey/Green/Yellow |

| 12mm | 22.5 | 3660mm x 1220mm | Grey/Green/Yellow |

< Scroll the table horizontally for the details >