The AlphaRiser® story

Comtec has produced thousands of square metres of grating and supports for service riser apertures over the last few years. This depth of experience has taught us that the management of service risers is one of the really difficult challenges for construction projects today.

It would be wonderful if the mechanical and electrical services could be perfectly planned at the start of a project and this design used to produce aligned drawings which didn’t need to be altered at any stage during the project.

The unfortunate reality is, however, that service designs always change due to their inherent complexity. Changes during the latter part of the design stages impact service requirements. Late placing of orders with M&E contractors mean designs are often far from complete when the floor construction has begun. An additional piece of equipment is asked for and immediately a larger supply is required. The shape and size of ducting was unknown at the time of forming the riser opening and its size unexpected. It was difficult to get all the service contractors around the table at one time and at an early stage in the design process which has impacted the design program. All these possible scenarios plus a multitude of others, explain why this area of the project is a difficult one to manage.

At Comtec, we have witnessed our customers wrestling with these challenges all too often and we have become increasingly passionate about the need for good Riser Management. This is a term we feel we own, and it embodies our drive to help site management in any and every way we can to improve… from here was born – the AlphaRiser*.

*Patent applied for

What is AlphaRiser® ?

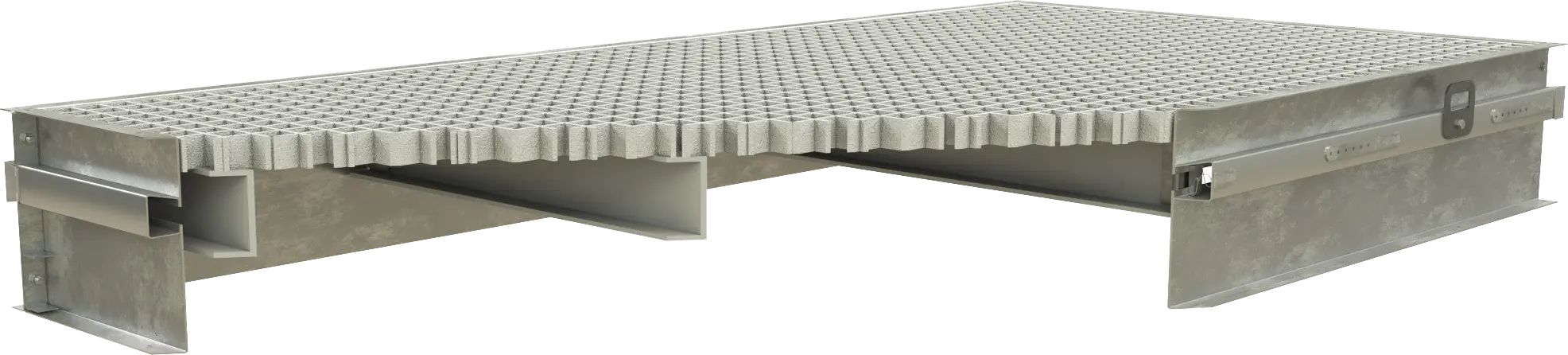

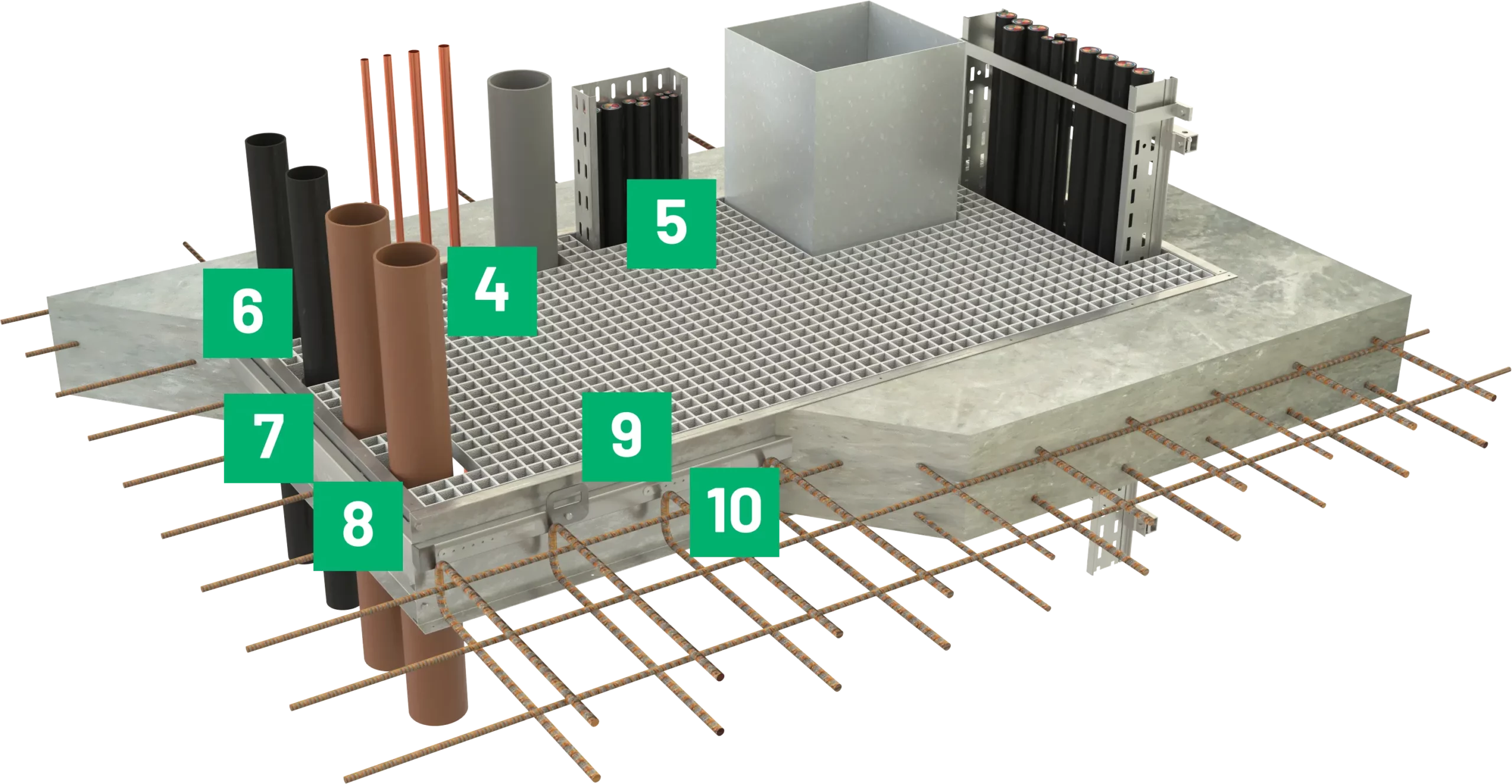

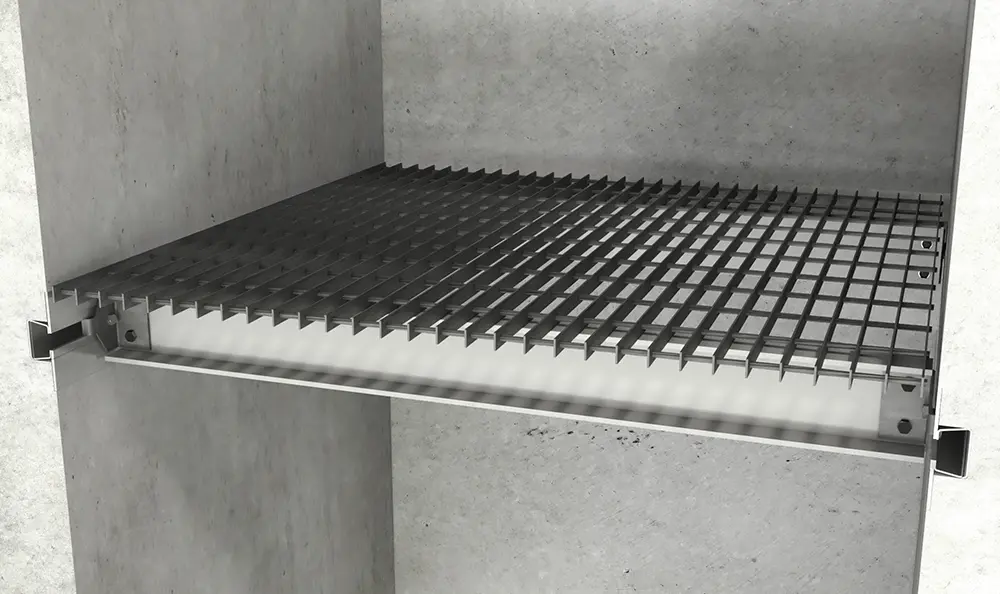

AlphaRiser is a lightweight, innovative and multi-faceted solution for service riser floor apertures – a unique combination of design ideas to assist in Riser Management. It makes specifying, designing, installing, and even adjusting the riser unit very easy. It is central to our Riser Management drive.

- AlphaRiser allows you to:

- Cast in a riser aperture frame early in the project without necessarily knowing the exact locations of the services at that time

- Install a riser floor unit very quickly

- Discount the need for any shuttering

- Discount the need for any barriers around the floor aperture

- Have complete peace of mind for the safety of site personnel working on the floor construction and beyond

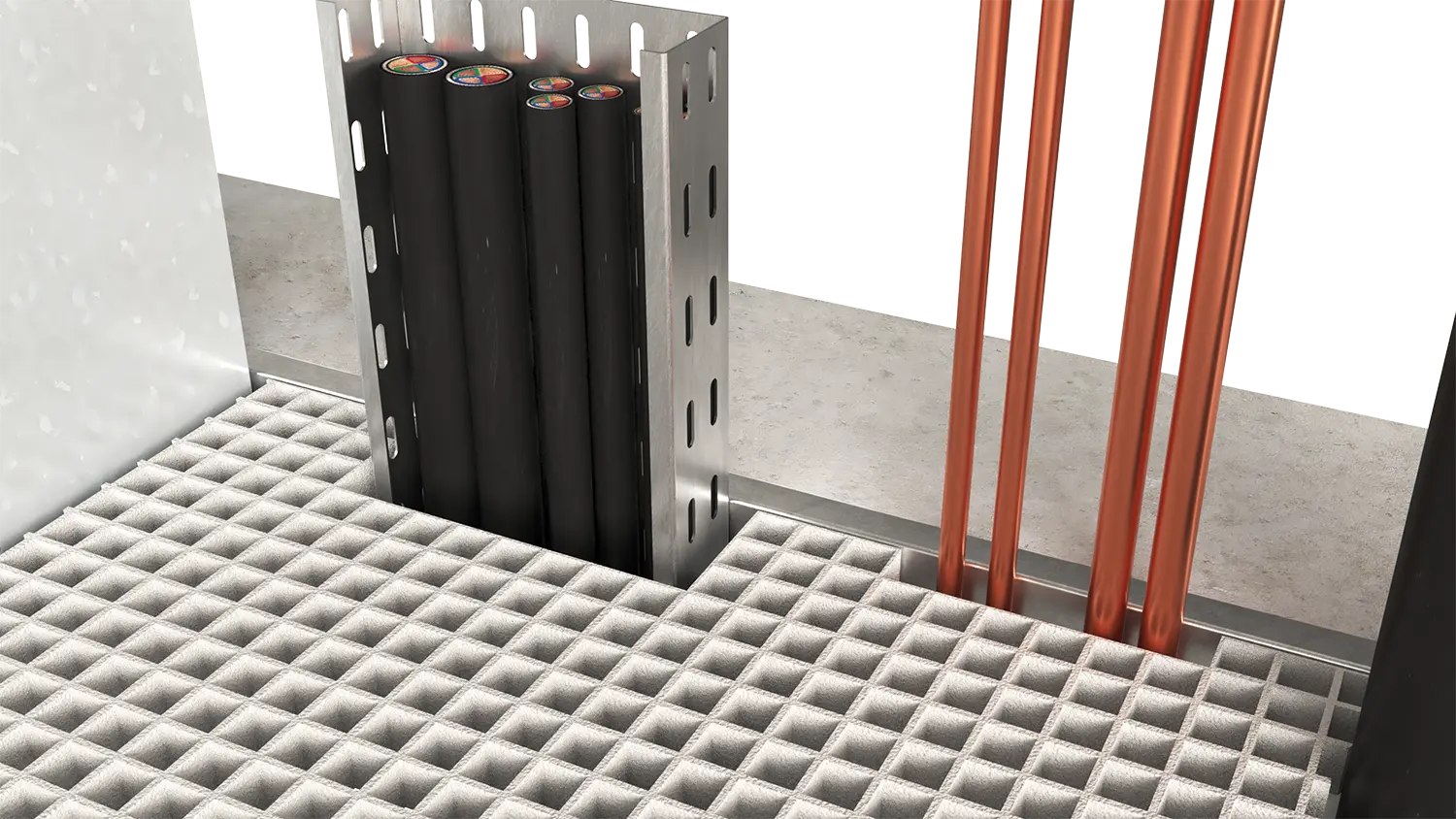

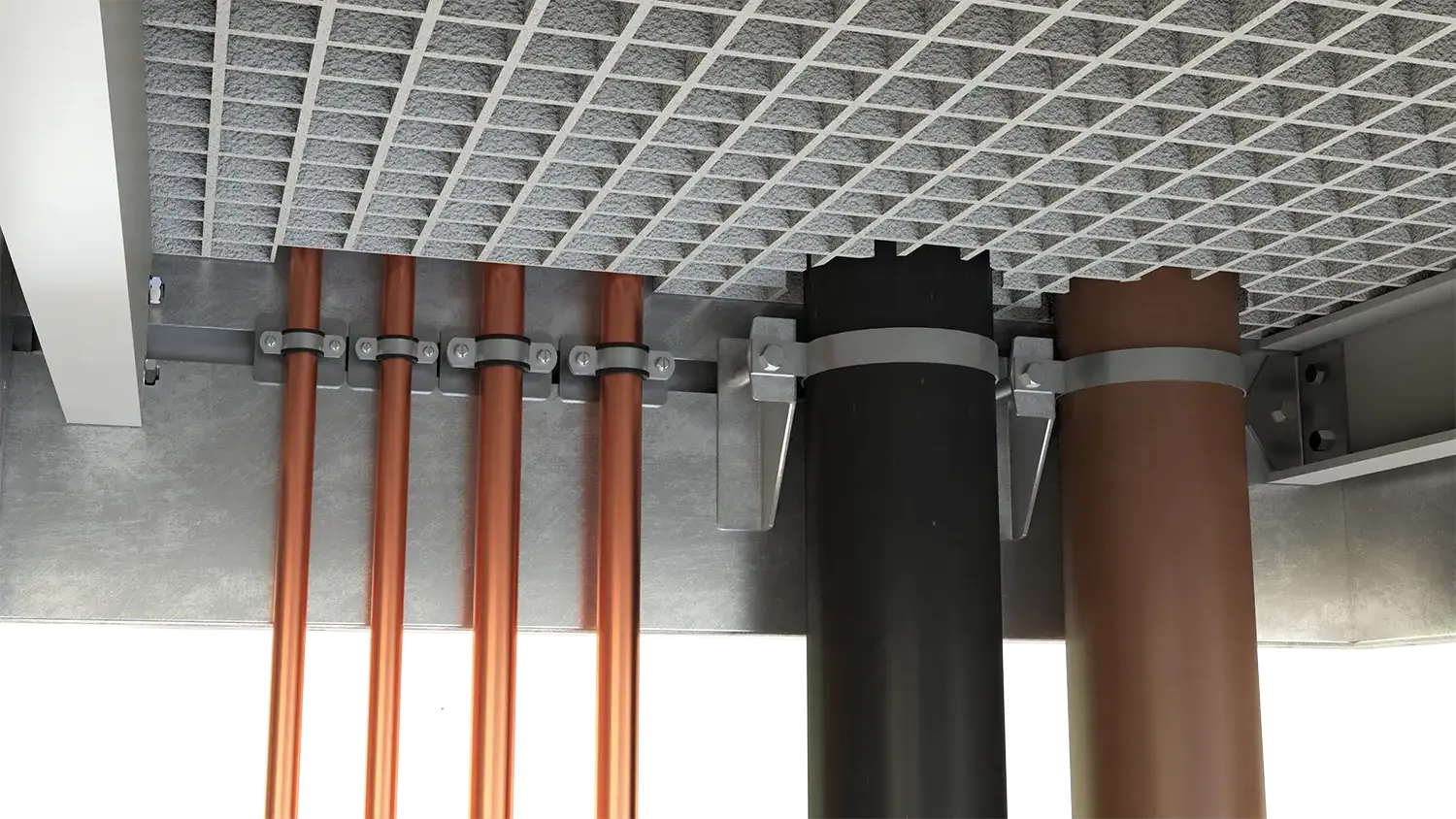

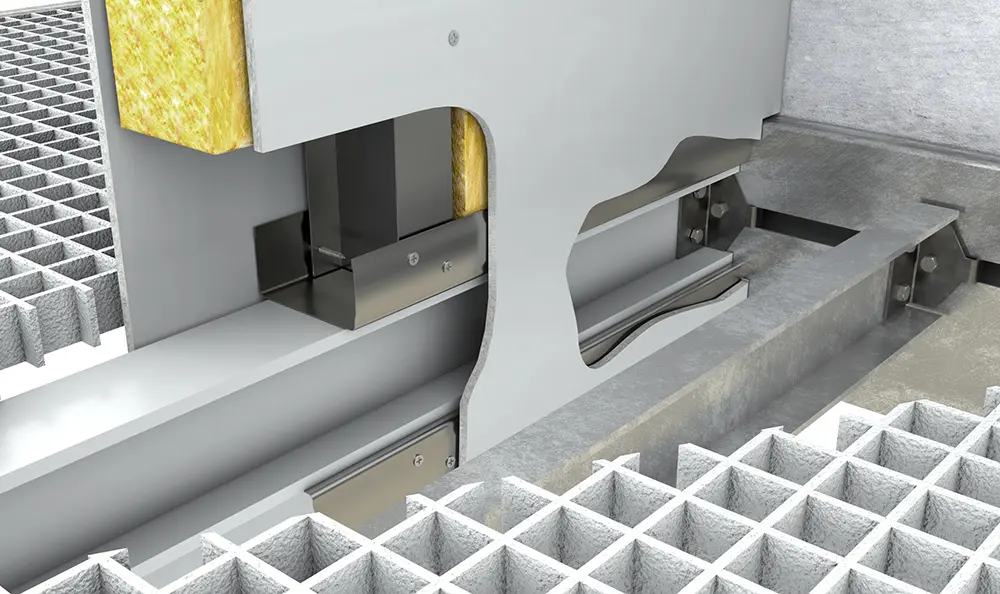

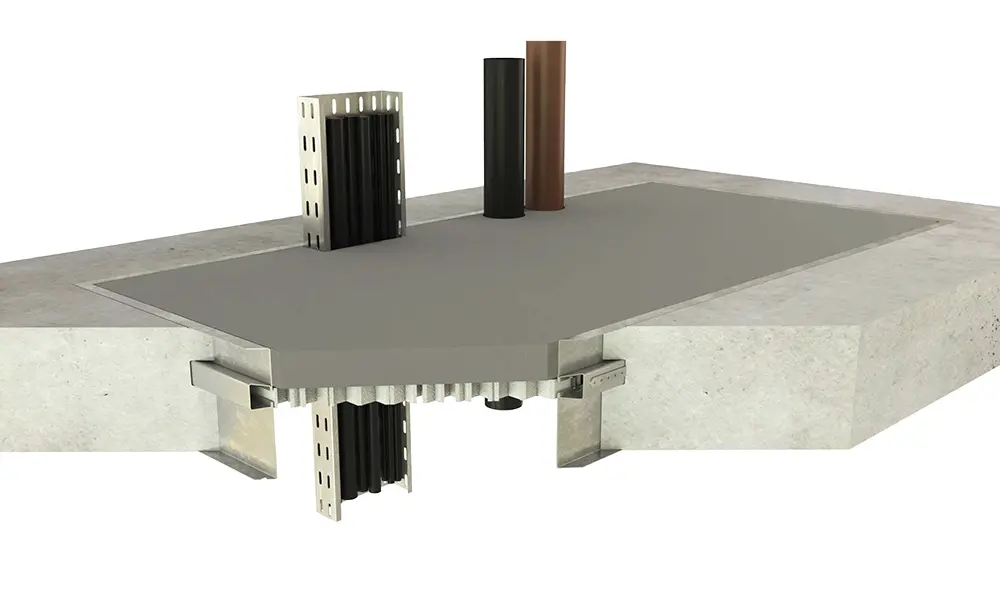

- Provide a strong edge frame which incorporates a cast-in AlphaRiser channel so that grating supports can be moved easily, new ones added, or existing ones removed very simply

- Fix services directly into the AlphaRiser channel mentioned above

- Discount the need for hot work permits during any adjustments

- Easily cut out the grating for services after installation once the service riser requirements are known

- Pre-fit AlphaRiser channels into building core walls whether using the Jump Form or Slip Form casting process

- Produce a complete specification or requirements list from our product portfolio to cover any element of building riser management needs

Why use AlphaRiser® ?

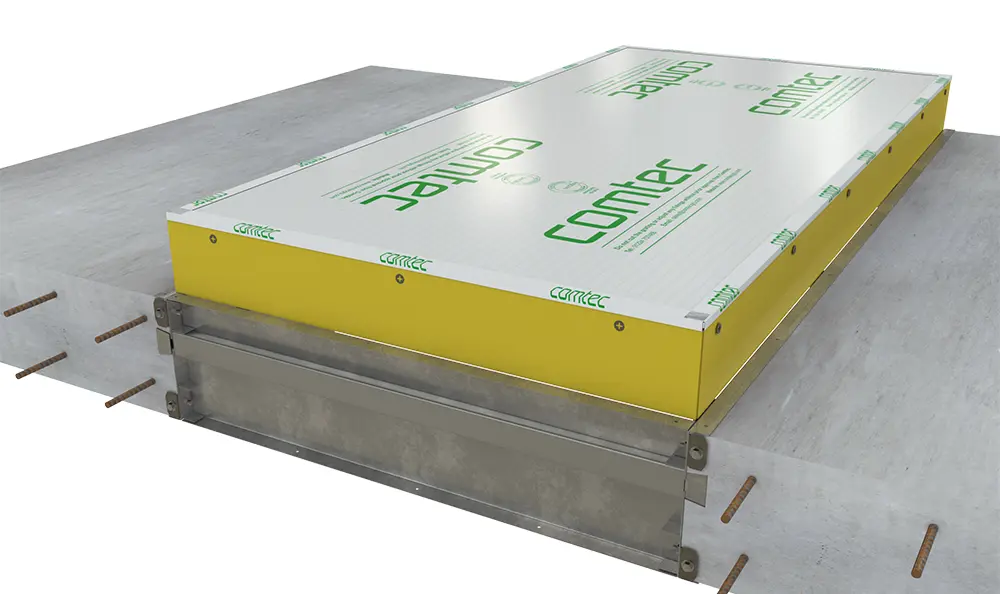

AlphaRiser is a unique and innovative, bespoke riser system for casting into concrete floor slabs

- 100% off-site manufactured unit ensures safety, removing the need for temporary protection

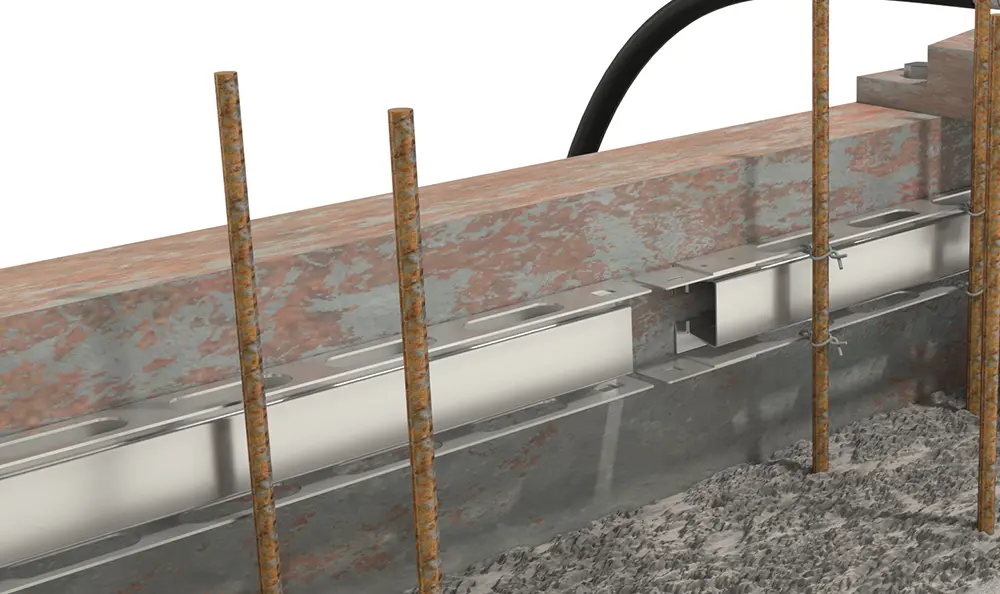

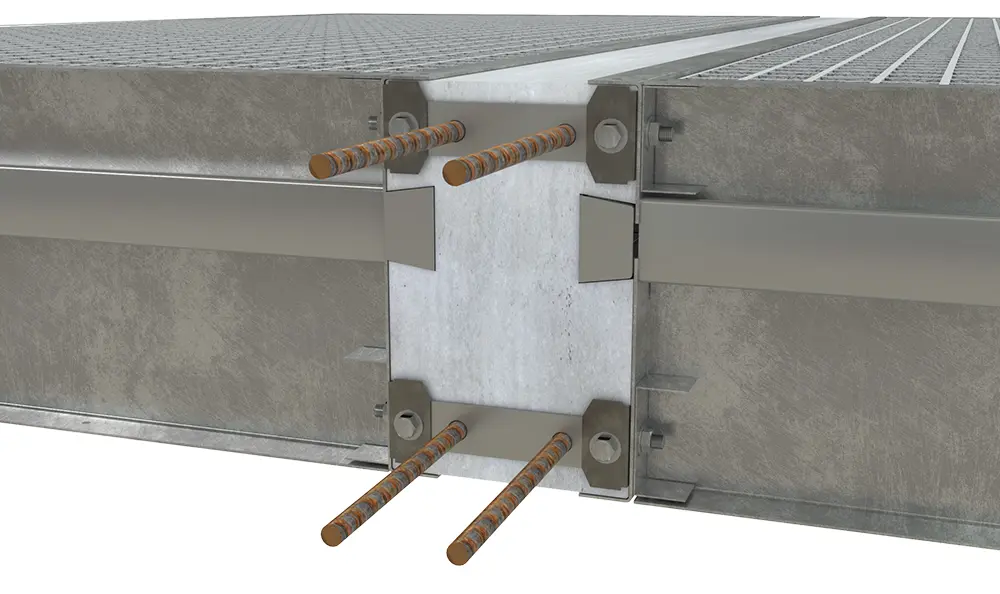

- Joist positions can be simply moved by sliding or adding connections along the channels

- Meets requirements for fire safety

- Simple to cut for services – no special tools, labour or hot-works permits needed

- Facility to fix supports for M&E and HVAC services

- Savings on formwork shuttering and fixings

- Strong unique channel design able to take heavy service weights

- Very lightweight and easy to move, handle and fit

- Corrosion resistant product with neat and tidy finish

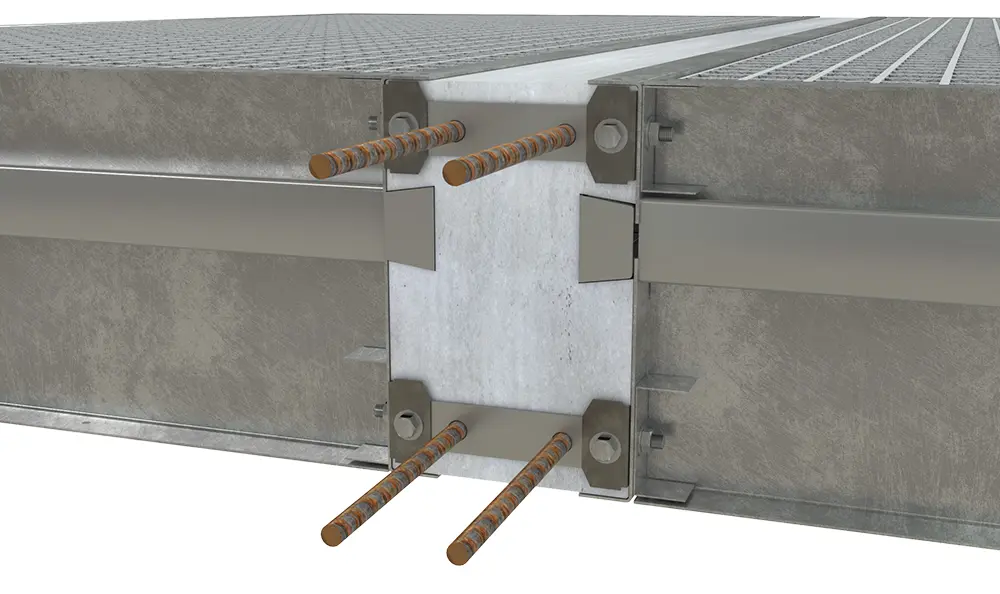

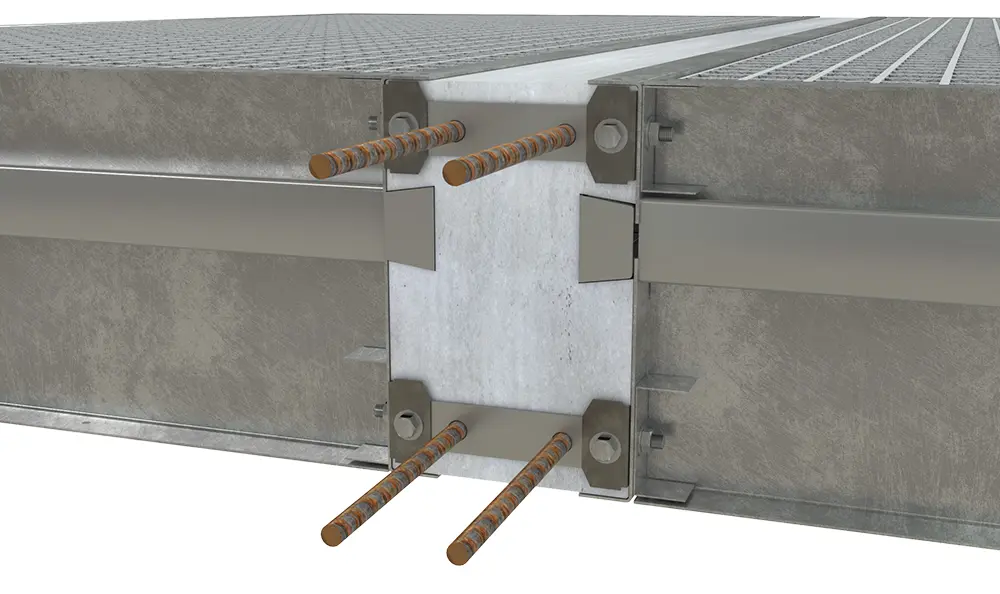

- Holes for fixing to casting deck and bend-out links for rebar coupling if needed

The AlphaRiser® Range

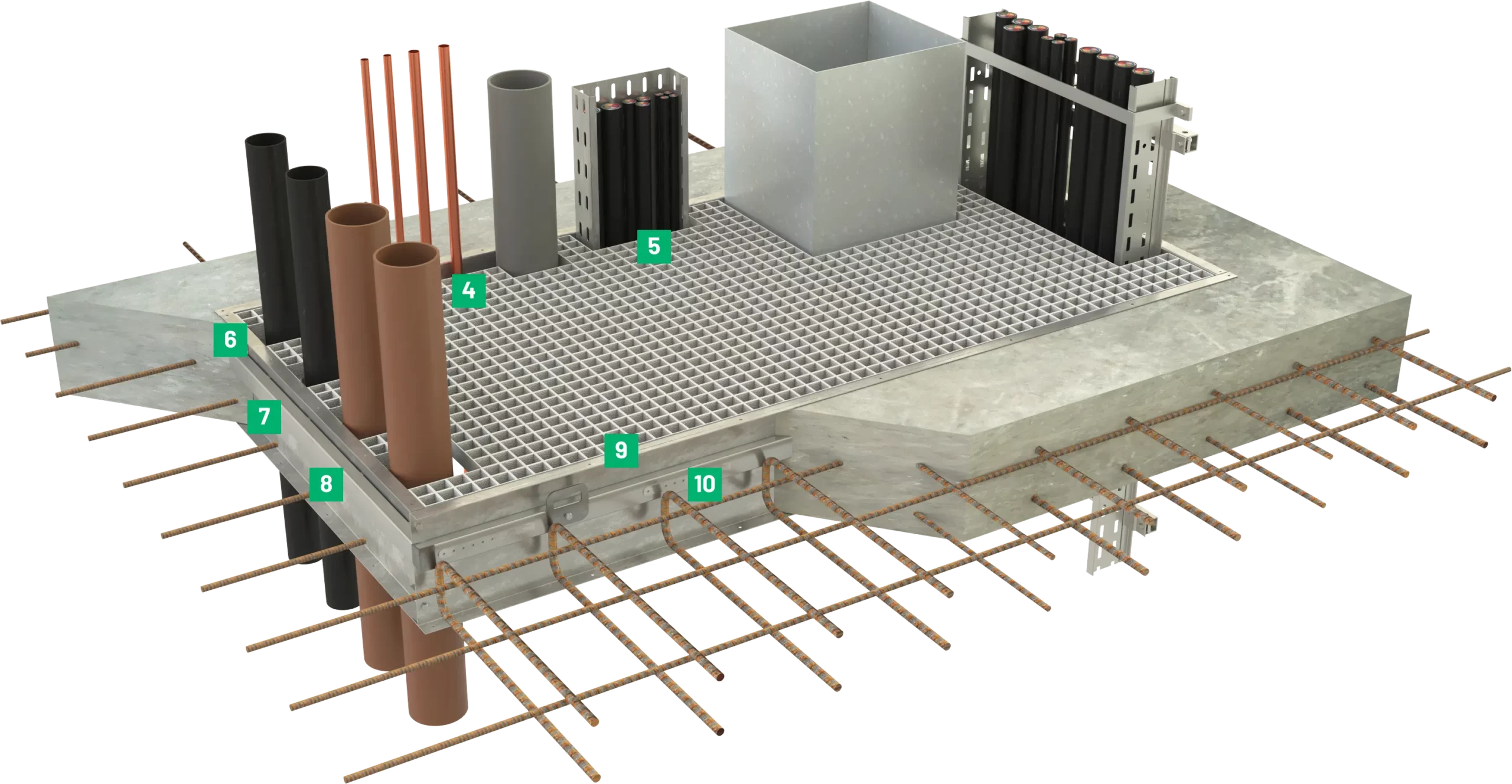

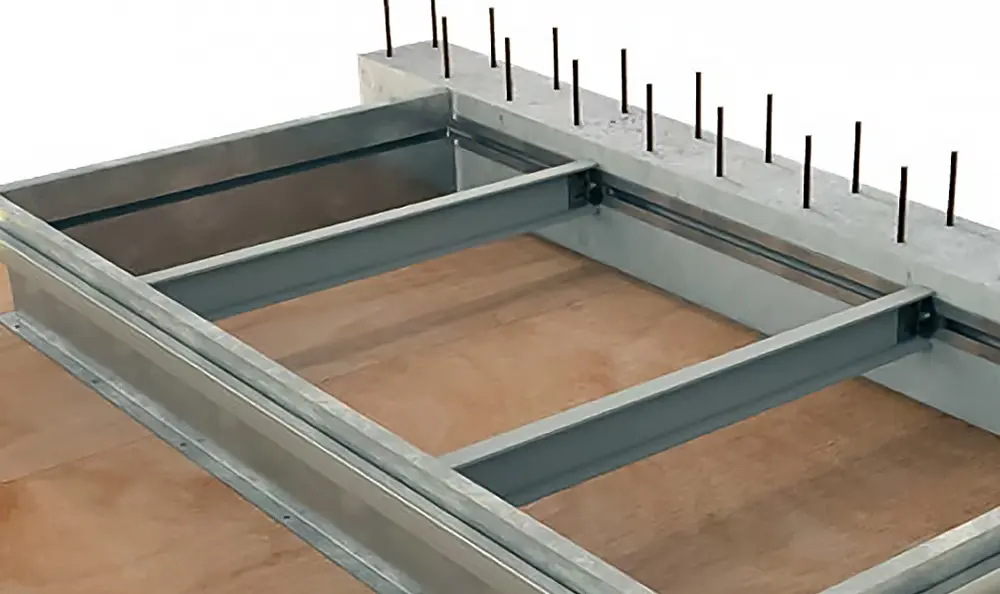

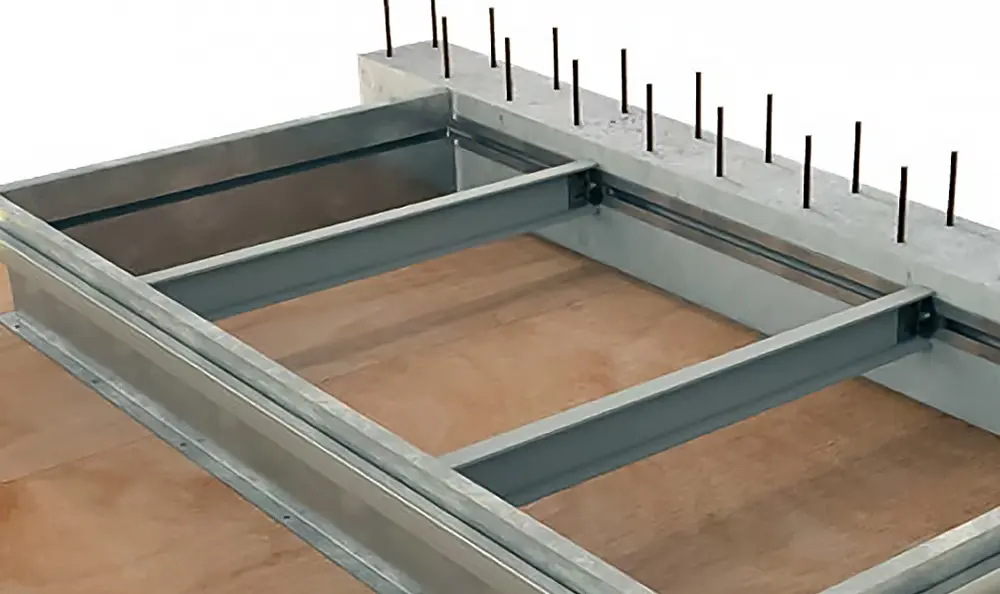

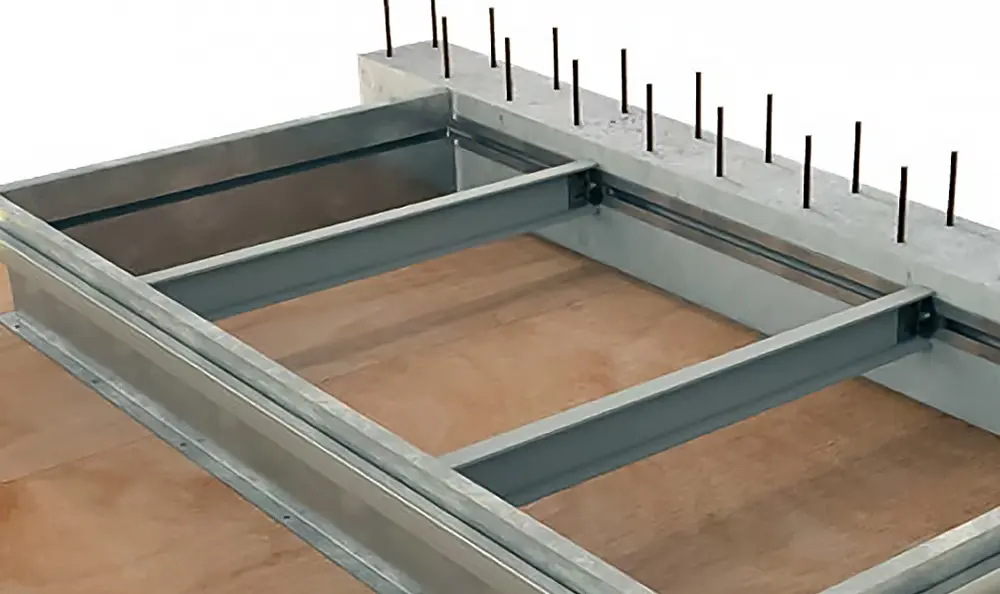

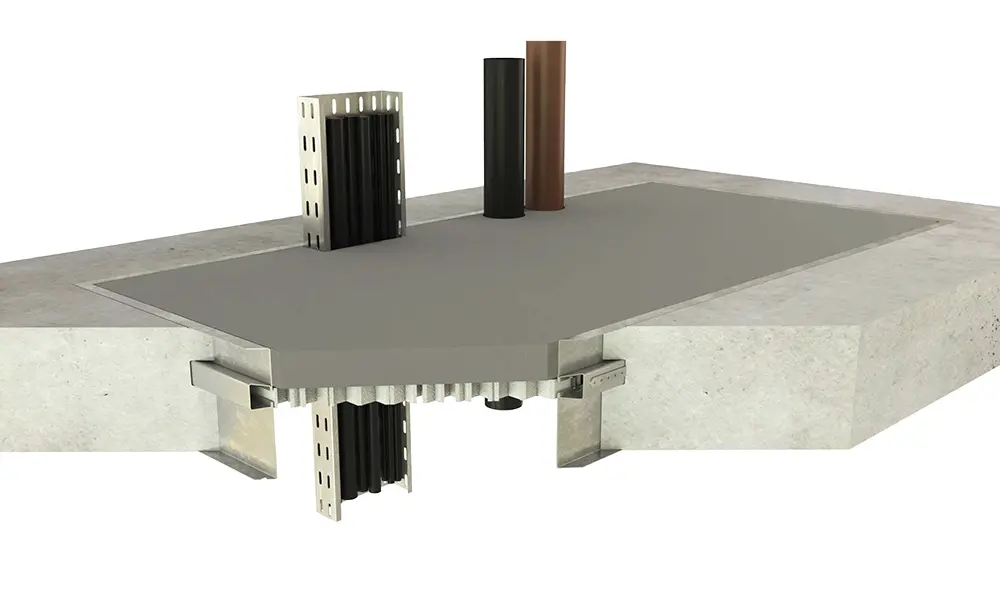

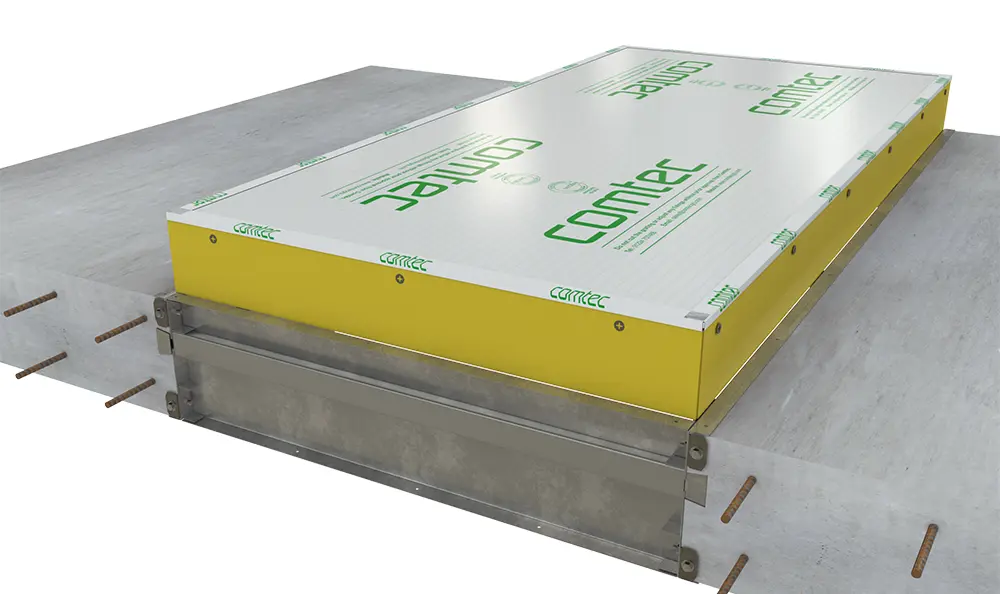

CIR – Cast-in Riser

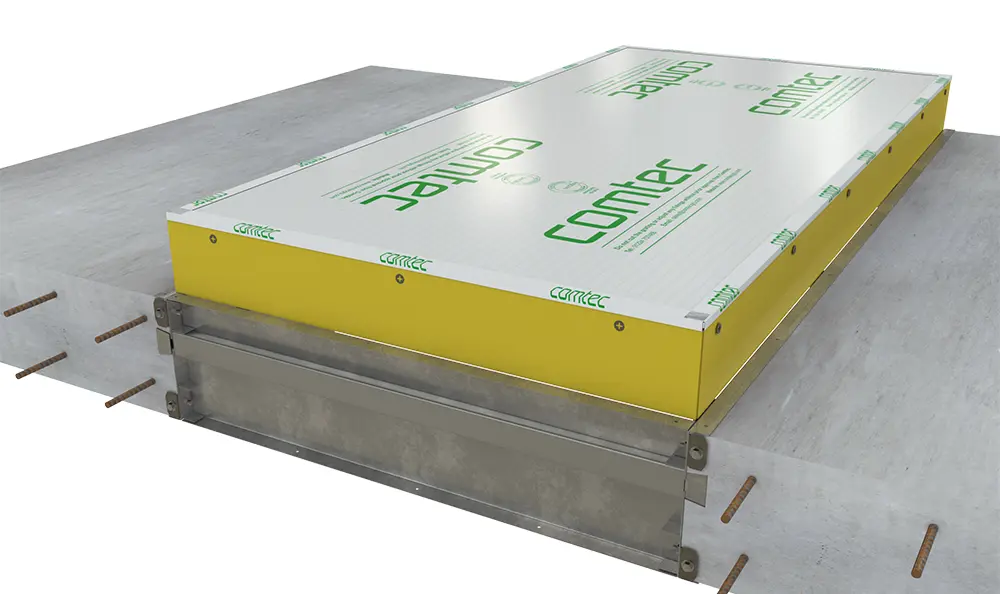

A completely premade unit, built in our factory and shipped to site ready to be simply lifted into position, screwed to the floor casting deck, and concreted around.

CWL – Cast Wall Link

A version which has the advantages of the CIR for two or three of its sides but where the other sides are fixed to a pre-built wall.

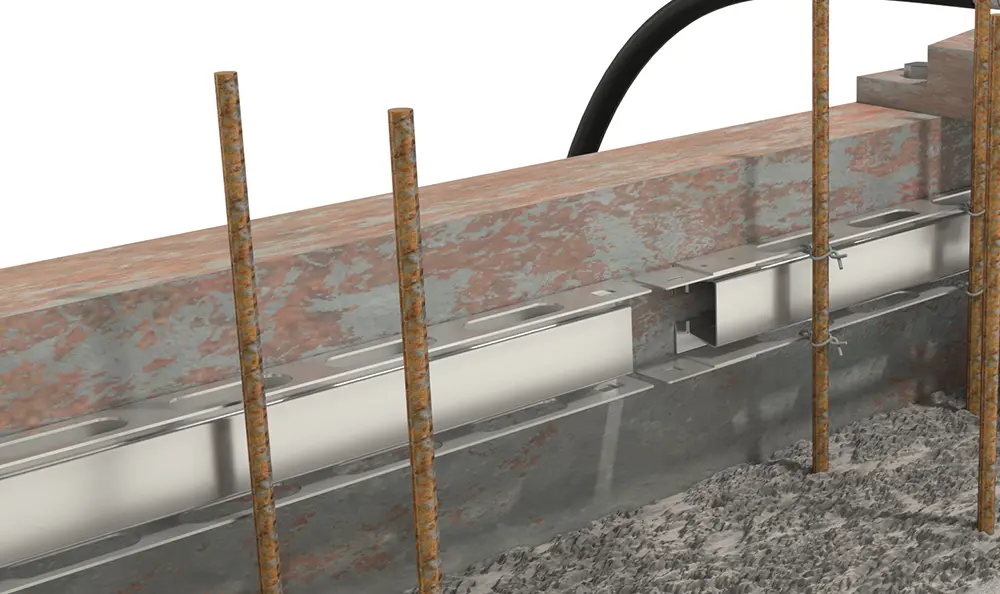

JF – Jump Form

This version provides a complete package of items required to insert AlphaRiser channels into a core wall or other concrete cast wall situation.

SF – Slipform

Like the JF version but having steel angle plates assembled to the AlphaRiser channel which can be rapidly fixed into a Slipform wall during construction.

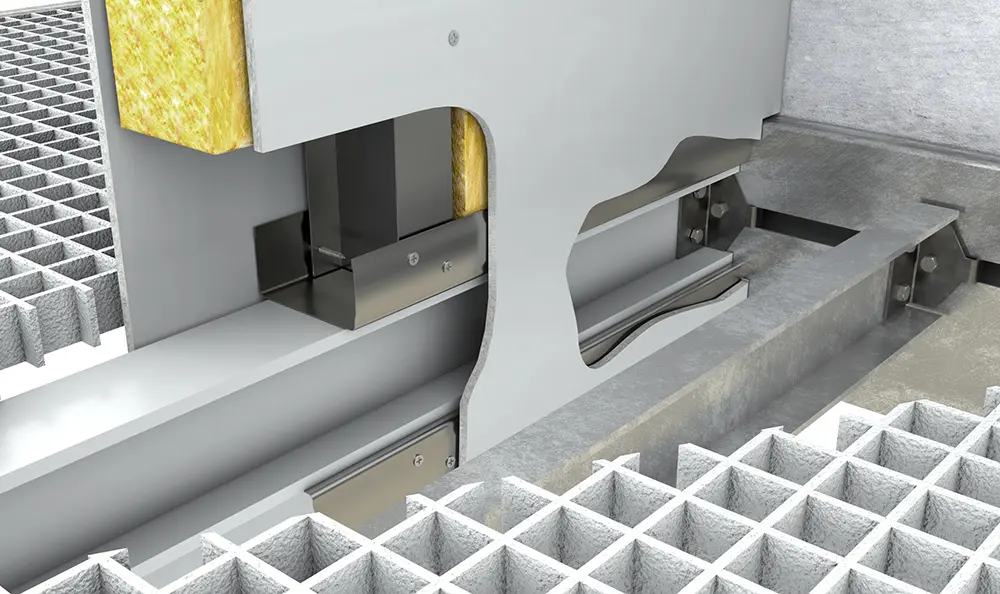

FR – Fire Resistant

This is a version of the other AlphaRiser designs giving the facility to incorporate a proprietary fire stopping compound system, achieving a 240 minute fire integrity.

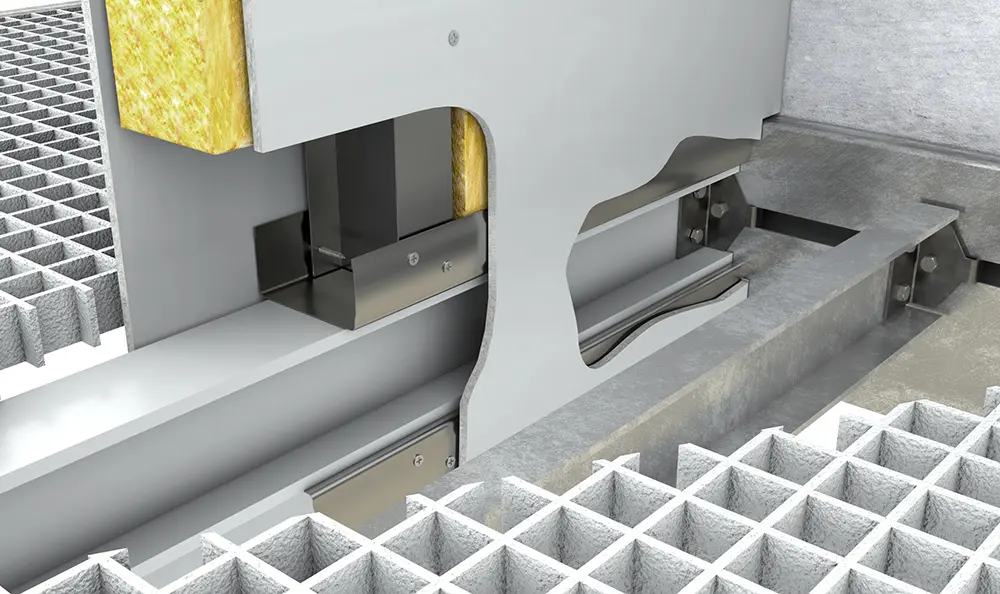

RA – Raised Access

This version has the benefits of the CIR but the grating and supports are raised to finish flush with the raised access floor level.

Adjustable WallBeam

A sliding beam to support dividing walls in an AlphaRiser unit.

WallBeam FR

A fire resisting support for dividing walls between AlphaRiser units.

SS – Smoke Shaft

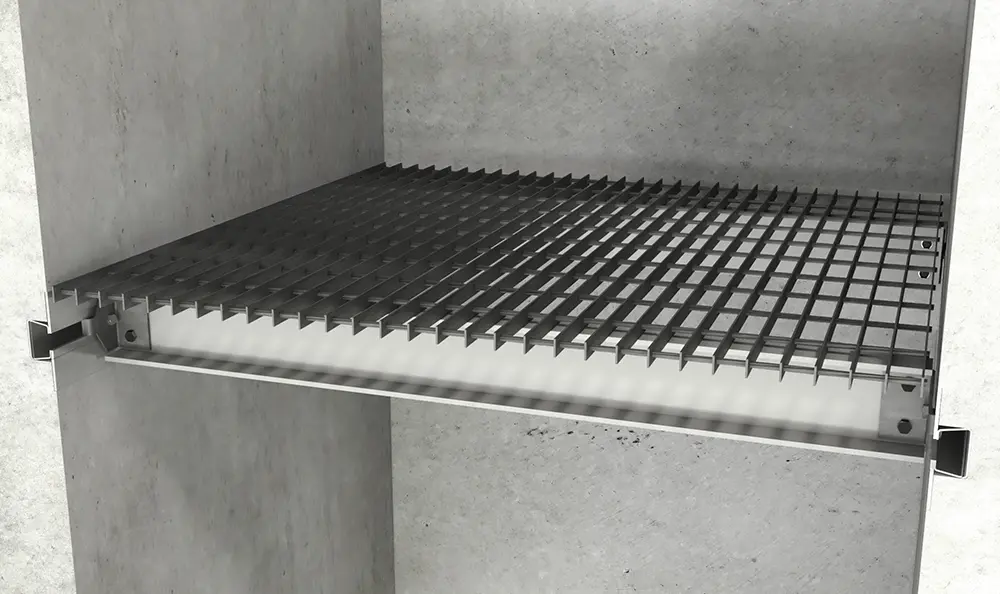

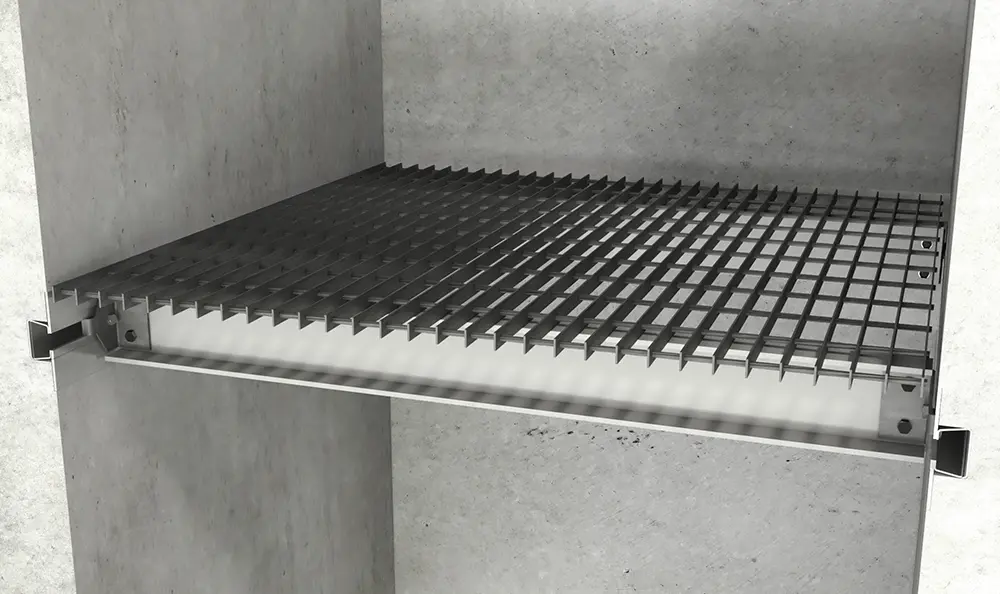

This version provides access platforms in smoke shafts.

NJ – No Joist

The NJ (no joist) version is particularly suitable for smaller risers.

The AlphaRiser® Range

CIR – Cast-in Riser

A completely premade unit, built in our factory and shipped to site ready to be simply lifted into position, screwed to the floor casting deck, and concreted around.

CWL – Cast Wall Link

A version which has the advantages of the CIR for two or three of its sides but where the other sides are fixed to a pre-built wall.

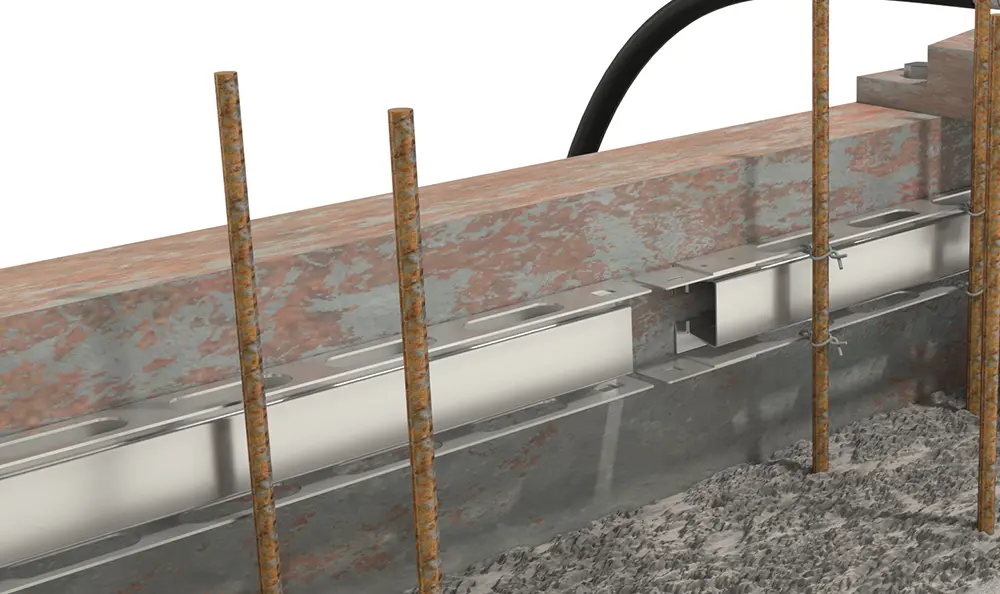

JF – Jump Form

This version provides a complete package of items required to insert AlphaRiser channels into a core wall or other concrete cast wall situation.

SF – Slipform

Like the JF version but having steel angle plates assembled to the AlphaRiser channel which can be rapidly fixed into a Slipform wall during construction.

FR – Fire Resistant

This is a version of the other AlphaRiser designs giving the facility to incorporate a proprietary fire stopping compound system, achieving a 240 minute fire integrity.

RA – Raised Access

This version has the benefits of the CIR but the grating and supports are raised to finish flush with the raised access floor level.

Adjustable WallBeam

A sliding beam to support dividing walls in an AlphaRiser unit.

WallBeam FR

A fire resisting support for dividing walls between AlphaRiser units.

SS – Smoke Shaft

This version provides access platforms in smoke shafts.

NJ – No Joist

The NJ (no joist) version is particularly suitable for smaller risers.

The AlphaRiser® Range

CIR – Cast-in Riser

A completely premade unit, built in our factory and shipped to site ready to be simply lifted into position, screwed to the floor casting deck, and concreted around.

CWL – Cast Wall Link

A version which has the advantages of the CIR for two or three of its sides but where the other sides are fixed to a pre-built wall.

JF – Jump Form

This version provides a complete package of items required to insert AlphaRiser channels into a core wall or other concrete cast wall situation.

SF – Slipform

Like the JF version but having steel angle plates assembled to the AlphaRiser channel which can be rapidly fixed into a Slipform wall during construction.

FR – Fire Resistant

This is a version of the other AlphaRiser designs giving the facility to incorporate a proprietary fire stopping compound system, achieving a 240 minute fire integrity.

RA – Raised Access

This version has the benefits of the CIR but the grating and supports are raised to finish flush with the raised access floor level.

Adjustable WallBeam

A sliding beam to support dividing walls in an AlphaRiser unit.

WallBeam FR

A fire resisting support for dividing walls between AlphaRiser units.

SS – Smoke Shaft

This version provides access platforms in smoke shafts.

NJ – No Joist

The NJ (no joist) version is particularly suitable for smaller risers.

Versions

AlphaRiser has the versatility and functionality for use with most construction types.

- Cast in-situ concrete floor slabs

- Profile sheet deck

- Pre-cast floor panels

- Post-tensioned floor pockets

- Steel frame structures

- Raised access floors

- Panel formwork core and partition walls

- Slip form system walls

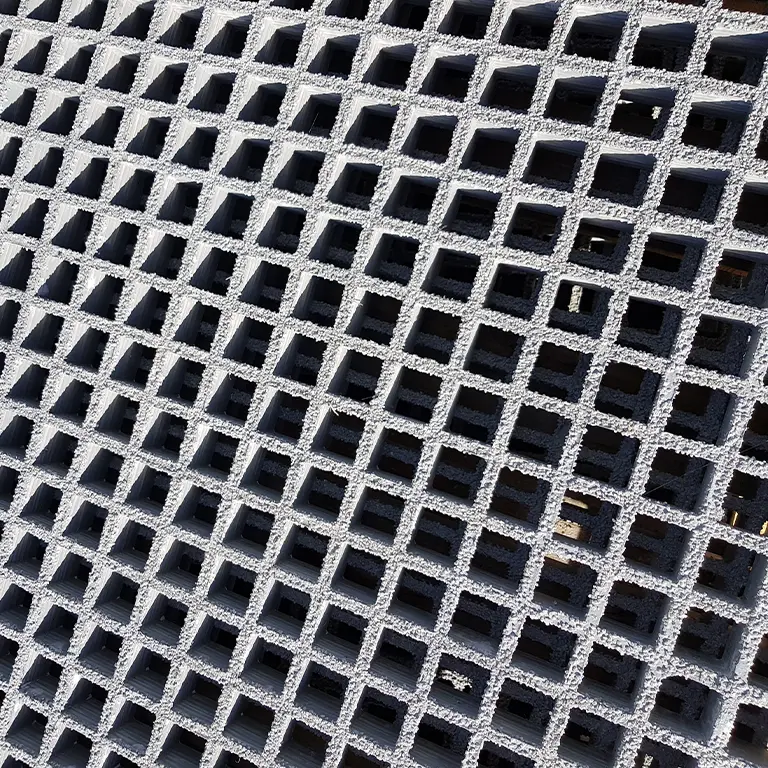

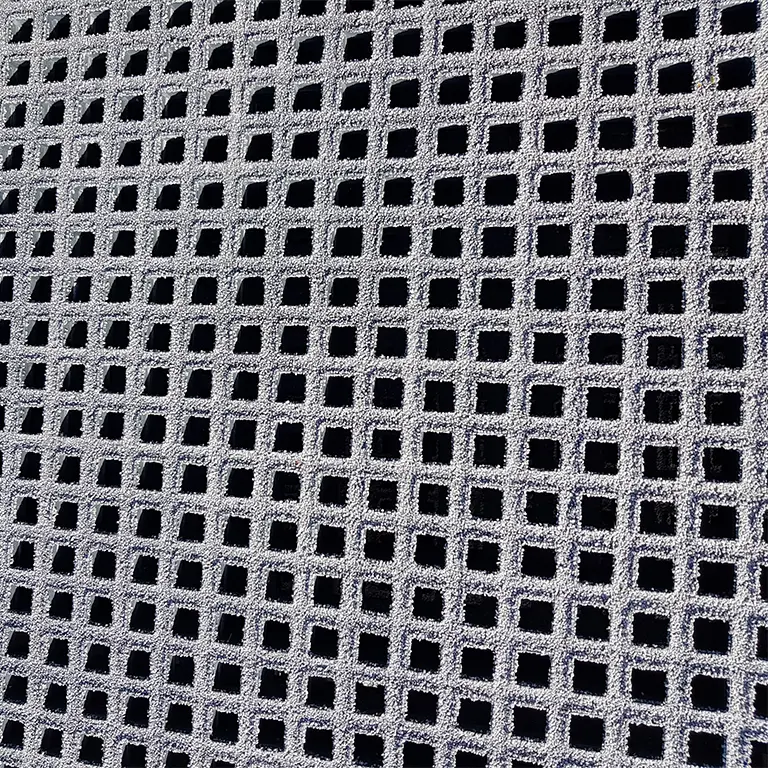

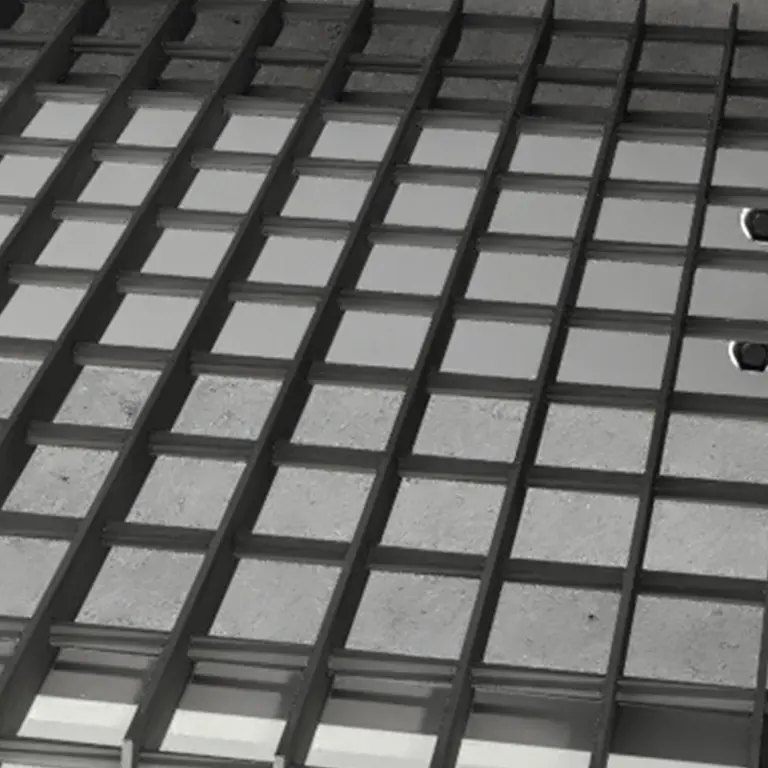

Standard mesh grating

Mini-mesh grating

Closed top grating

Steel grating (for smoke vent shafts)

Fire stopping compound

Installation

Casting deck formwork is constructed, typically starting from the first floor.

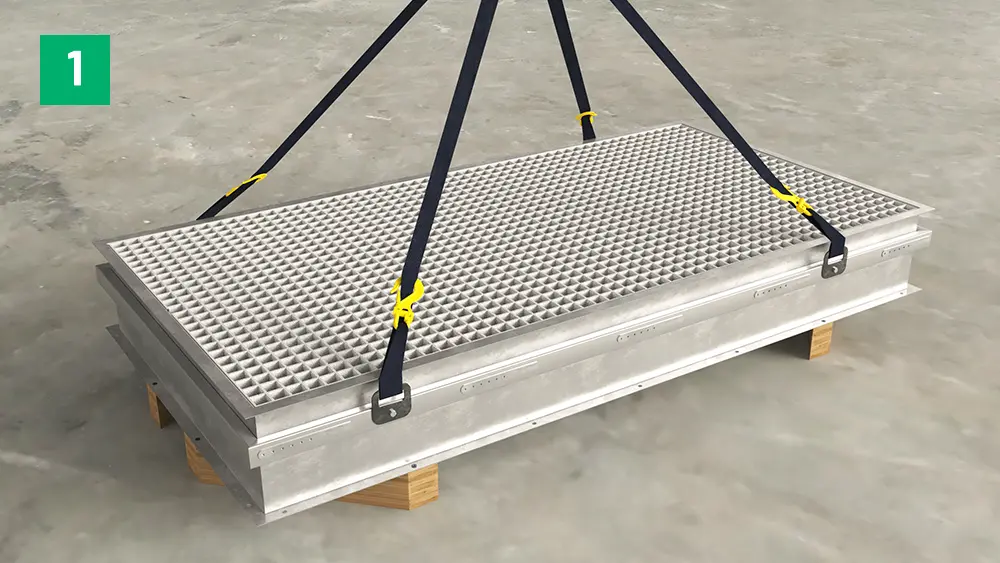

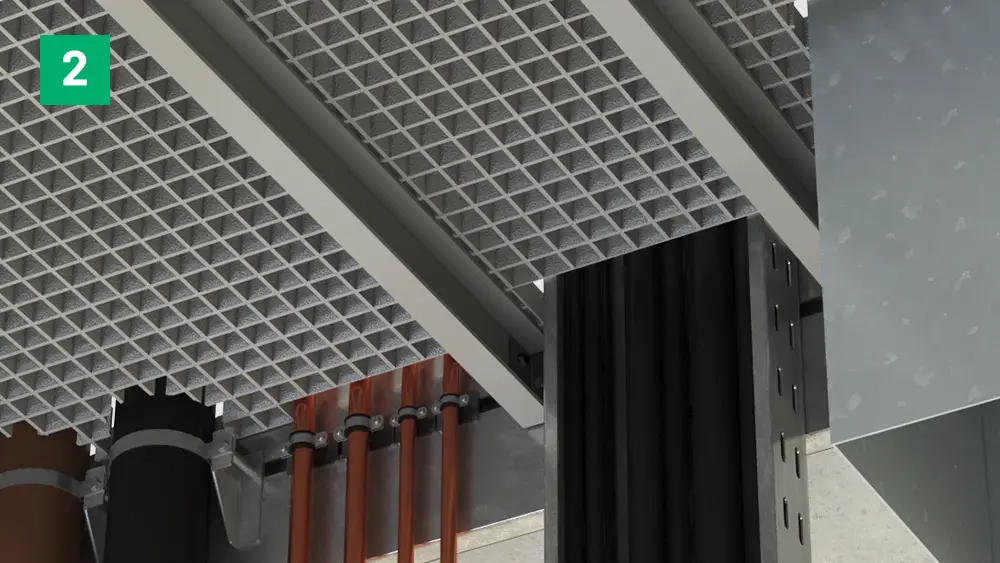

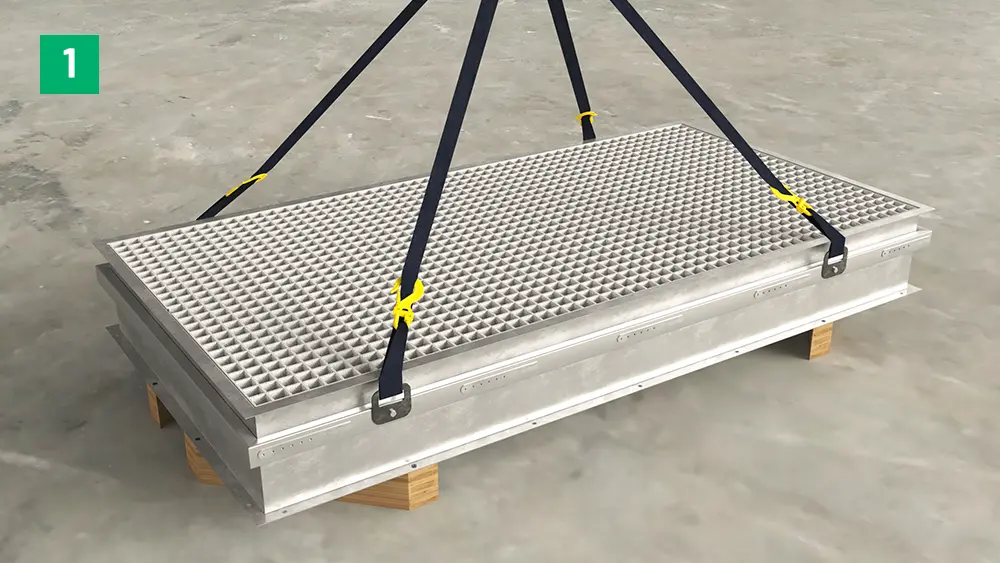

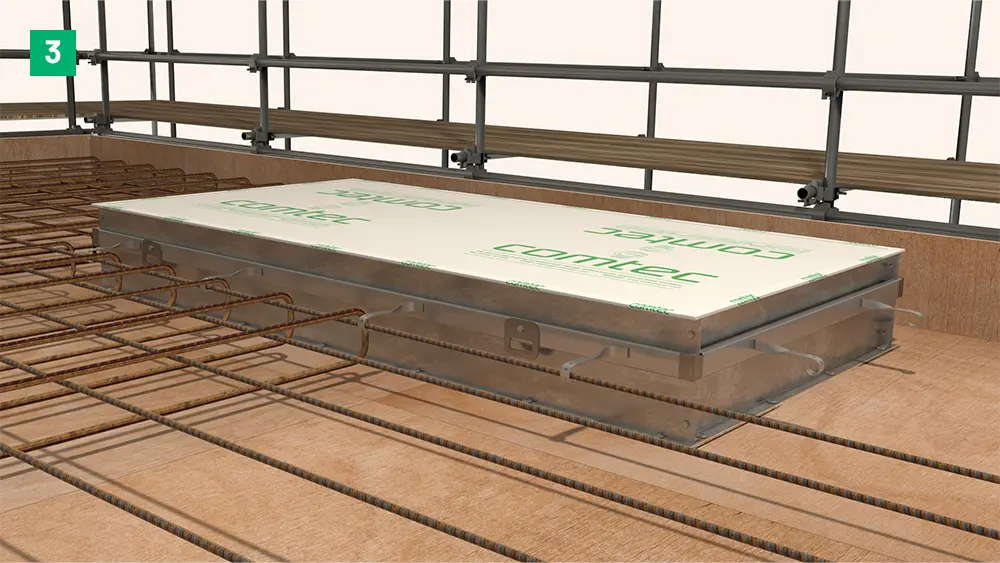

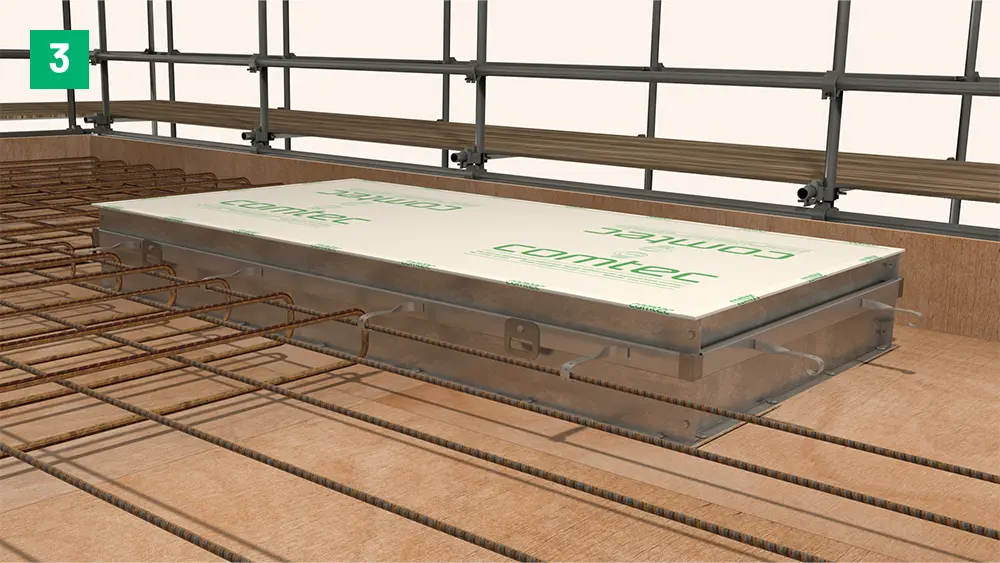

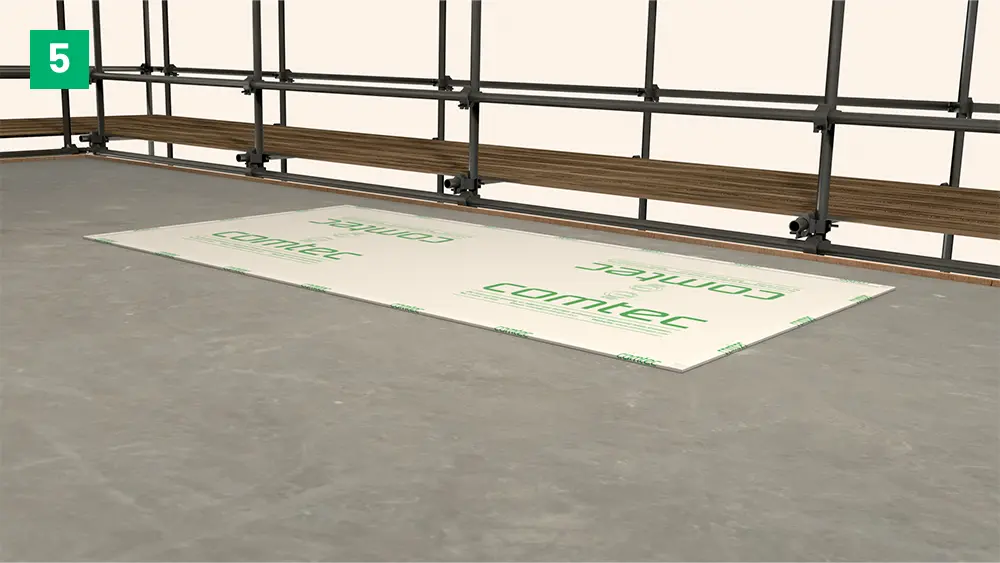

AlphaRiser is delivered to site pre-made and craned into position on the casting deck.

AlphaRiser is fixed to the deck in the marked position using flange head screws and the crane lifting plates are turned downwards away from the top rebar mat.

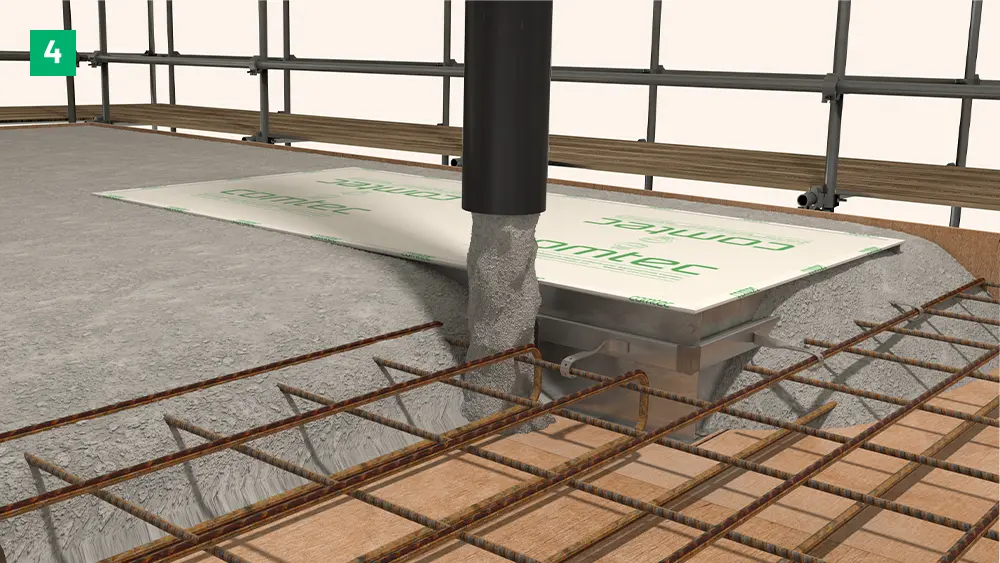

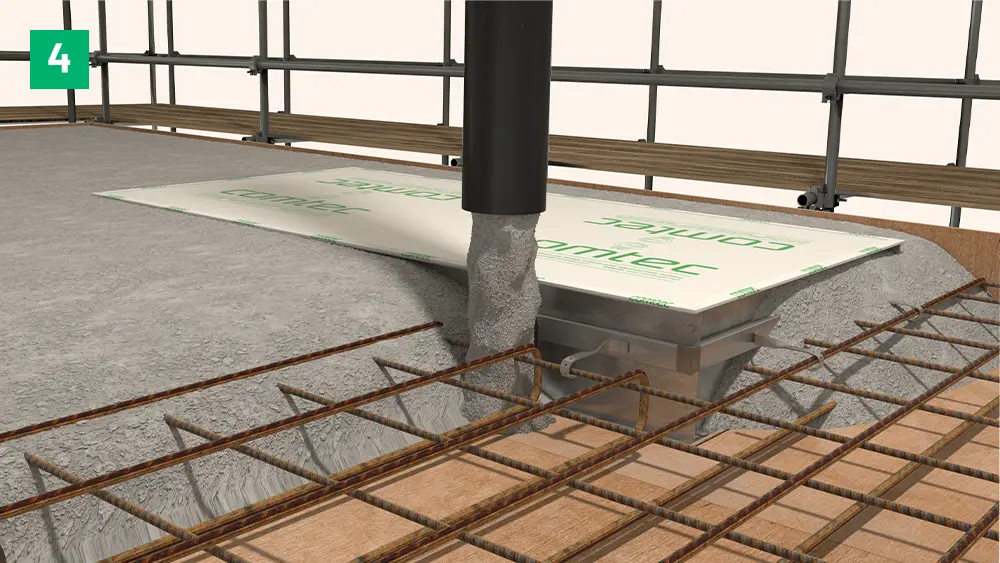

AlphaRiser forms a shutter for the concrete which can now be poured to form the floor and will encase it to create the service riser opening.

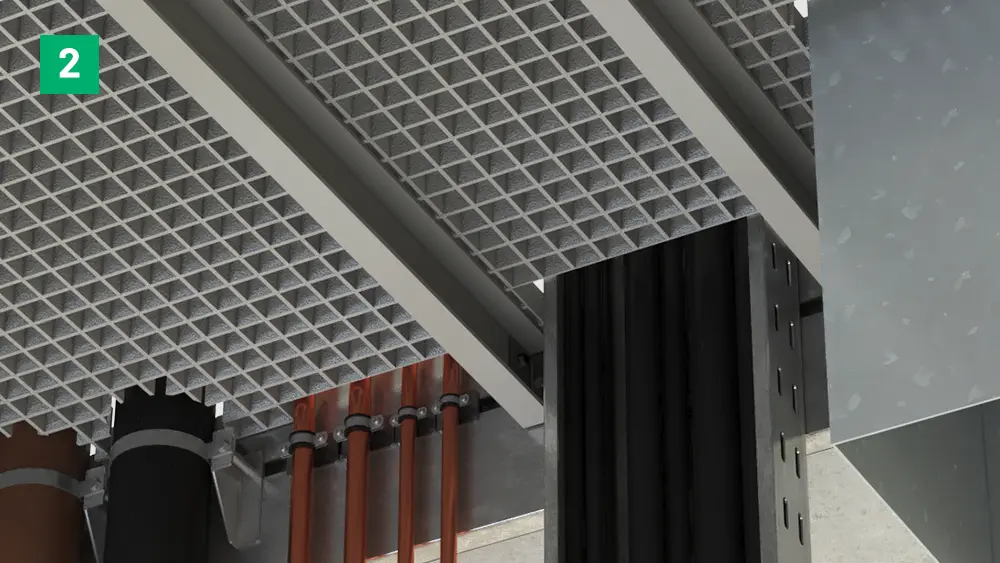

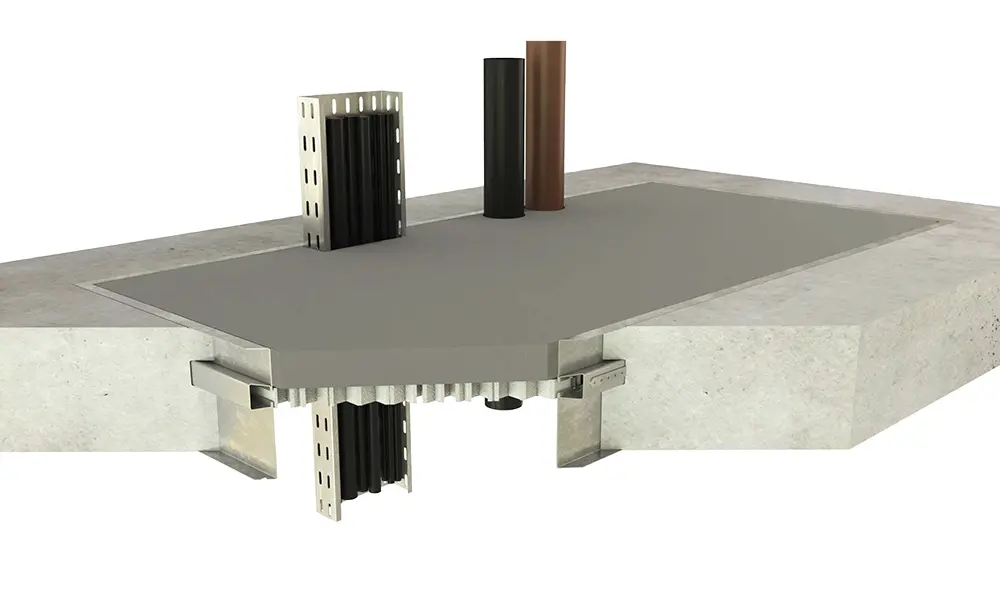

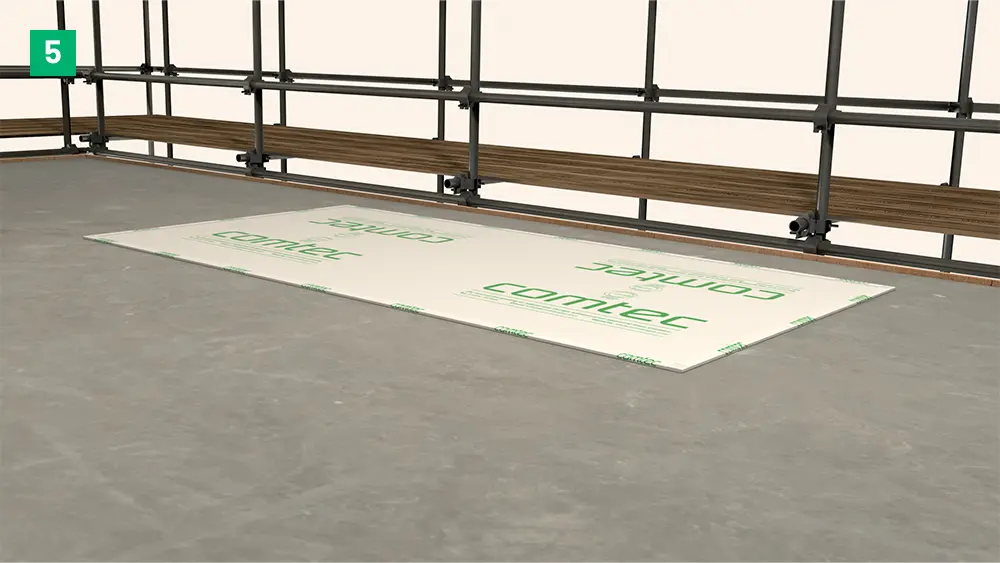

Once the concrete has cured, the casting deck is removed, the fixing screws are cropped, and the riser aperture in the floor is complete and ready for services to be installed.

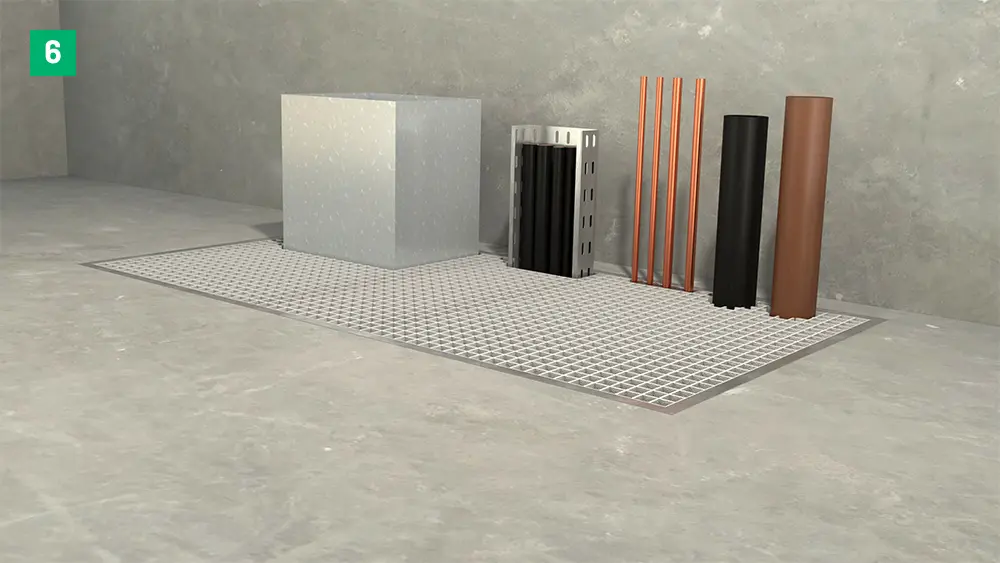

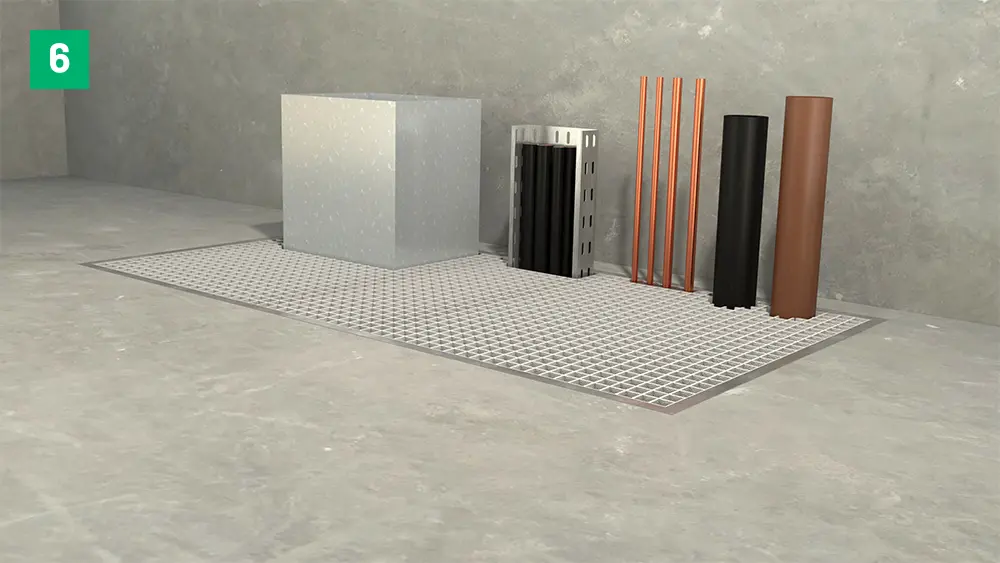

Walls are built and services are installed. The GRP grating can be simply cut away by the M&E contractor as needed to maintain a safe working platform. This will allow the service sections through and the sliding joists moved to allow unforeseen items to pass if needed.

Casting deck formwork is constructed, typically starting from the first floor.

AlphaRiser is delivered to site pre-made and craned into position on the casting deck.

AlphaRiser is fixed to the deck in the marked position using flange head screws and the crane lifting plates are turned downwards away from the top rebar mat.

AlphaRiser forms a shutter for the concrete which can now be poured to form the floor and will encase it to create the service riser opening.

Once the concrete has cured, the casting deck is removed, the fixing screws are cropped, and the riser aperture in the floor is complete and ready for services to be installed.

Walls are built and services are installed. The GRP grating can be simply cut away by the M&E contractor as needed to maintain a safe working platform. This will allow the service sections through and the sliding joists moved to allow unforeseen items to pass if needed.

Case Studies

A row of risers in this Comtec project in a metal profile deck floor construction for this health research facility.

Shapes are possible shown by this Comtec project in Aberdeen. The rebar is fitted and the slab ready to be poured.

The AlphaRiser JF channels are exposed once the shutter is removed and await fixing of the sliding joists and grating, for this Comtec project to a student accommodation block in Belfast.